MAURITECH SRL

Services

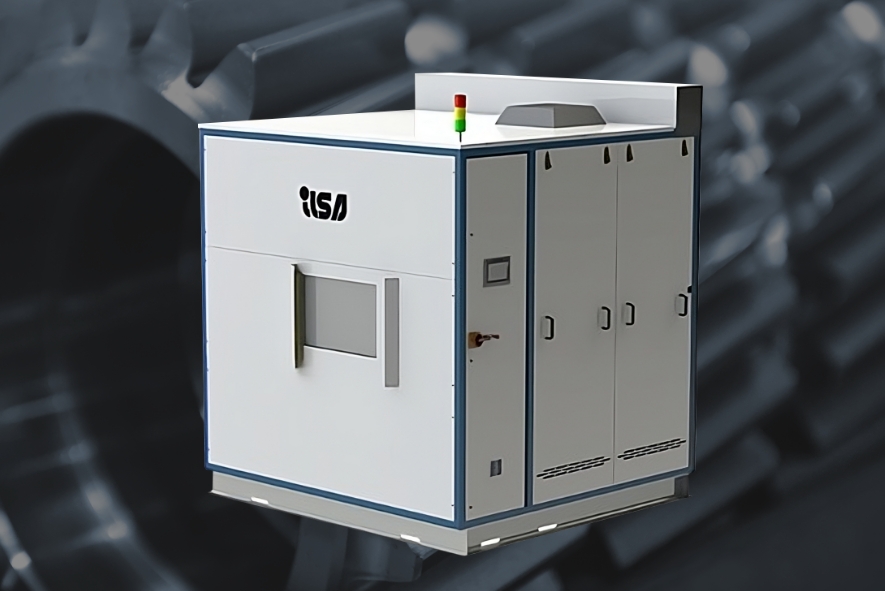

Wash

Once produced, the parts are placed in special boxes equipped with dividers and washed inside an ultrasonic metal washer using modified alcohol. The system is a closed cycle and the product used to clean the parts has low toxicity and ecotoxicity, evaporates completely and can be recycled by distillation. The washing programs are different: for this phase, as for the others, we evaluate the most suitable program for the component.

Packaging

The choice of the type of packaging to be used is studied carefully by evaluating the customer's requests in relation to the piece: whether it is aesthetic or particularly delicate, suitable packaging is prepared to prevent the item from suffering various types of damage during transport. We use mesh tubes of various thicknesses or bubble wrap bags or simple cardboard dividers. Upon customer request and supply, we can package the pieces in pre-formed trays. For items subject to corrosion we can apply a thin layer of oil and/or package the items in appropriate VCI bags.

Transport

Every day we entrust the shipments of manufactured parts to transporters we trust; we do our best to ensure that the component arrives free of any defects due to transport and in the shortest possible time. We rely on various couriers for small shipments and consolidated transporters for material on pallet. Generally, delivery takes place within 24 hours for the national territory, 4-5 days for Europe.

Heat / galvanic treatments

For years we have been providing our customers with finished parts also with heat, galvanic and surface treatments. We have created solid relationships with our partners to whom we outsource the treatment phases.

Heat Treatments

– Vacuum hardening

– Induction hardening

– Quenching in atmosphere

– Cementation

– Reclamation

– Carbonitriding

Surface Treatments

– White/black/yellow galvanizing

– Burnishing

– Nickel-Tin

– Zinc-Nickel

– Aesthetic Anodization

– Hard anodizing

External processings

In addition to the treatments, we are able to provide, always relying on consolidated contractors, the following processes: